Product Overview

paper rollFull-automatic Packing MachineIt is a type of packaging designed for the width of cylindrical productsWrap packaging machineThis machine is mainly suitable for wide surface wrapping of single cylindrical or multiple cylindrical sheet-like objects, and can be applied to both light and heavy products, playing a role in dust prevention, moisture prevention, and cleaning. At the same time, according to the actual needs of packaging, equipment such as automatic ejection, composite packaging, and online winding packaging machines can be selected.

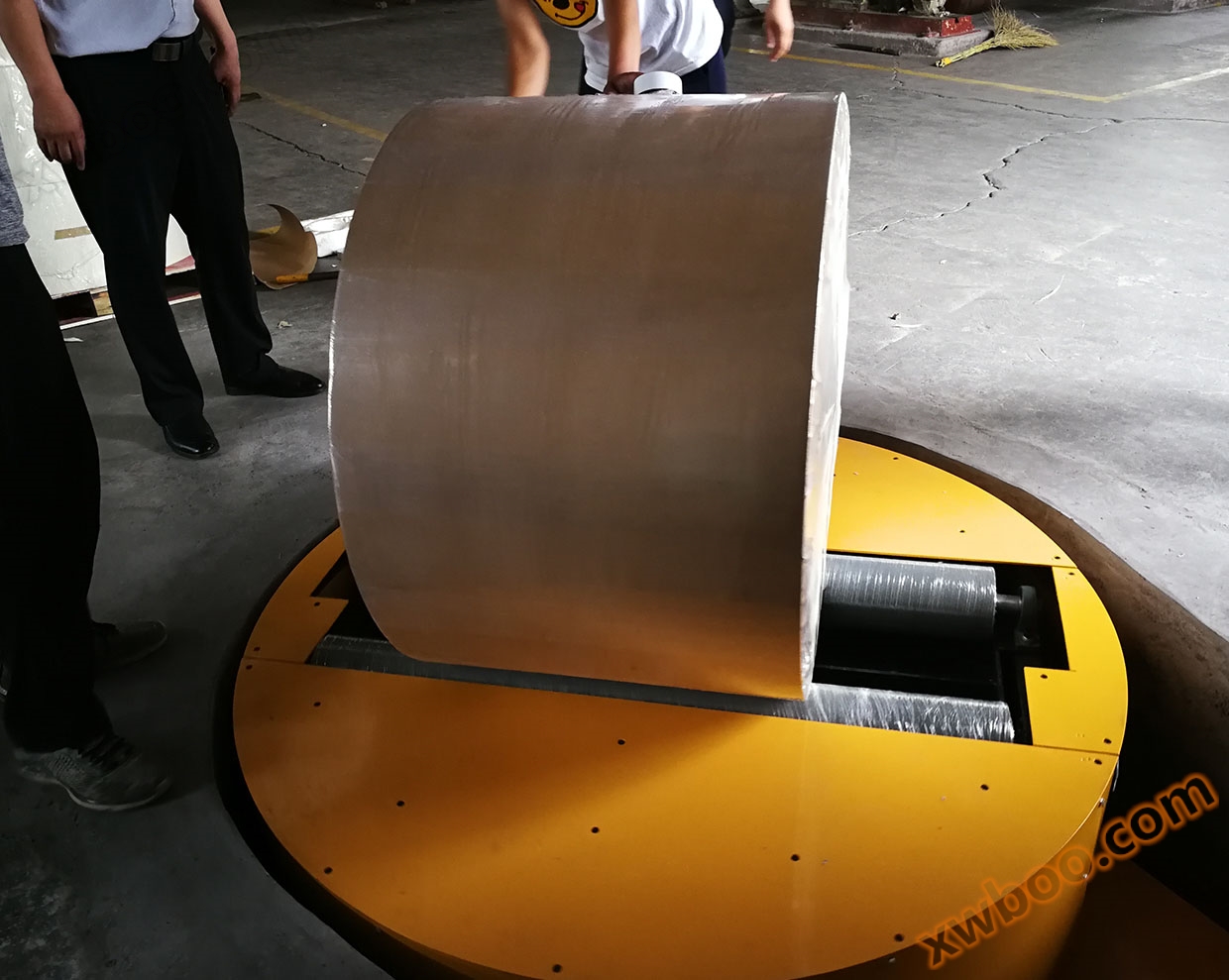

product image Packaging principle

Packaging process description: Set the number of packaging layers, adjust the position of the film frame to switch to cylinder machine mode, fix the wrapping film onto the goods to be packaged, press the "run" button, and there are two recessed rollers on the turntable. One of the active rollers rotates counterclockwise, which drives the cylindrical paper to rotate counterclockwise, and the turntable rotates clockwise at the same time. After running according to the established parameters, manually cut the film and package it. Technical data (customizable production according to user needs)

1. Technical parameters Key components

1.1) Packaging Range Diameter: 500mm-1200mm Width: 500mm-1600mm

1.2) Packaging efficiency Packaging efficiency: 20-30 pieces/hour (depending on the specific goods)

1.3) Rotary table size diameter: 1650mm height: 530mm

1.4) Rotary table load capacity 2000kg (max)

1.5) Rotary speed 0-12rpm/min

1.6) Whole machine weight 1000kg

1.7) Roller speed 0-12rpm/min

1.8) Motor power turntable 0.75KW film feeding 0.4KW lifting motor 0.4KW

1.9) Power supply single-phase 220V AC/50Hz/20A

1.10) Suitable for film 20-25 μ pre drawn machine winding film

2. Control system

2.1) PLC programmable control of the whole machine operation, adjustable winding layers and times

2.2) Humanized international panel icons for easier and simpler operation

2.3) Manual/automatic switching and reset buttons to ensure that the equipment does not malfunction and affect its performance; Protect the safety of operators.

2.4) Mechanical and photoelectric switching functions, allowing for free and convenient operation of the equipment.

3. Rotary drive

3.1) Star shaped layout with wear-resistant new nylon support wheels for low-noise operation

3.2) Rotary table variable frequency speed regulation, slow start slow stop automatic reset

3.3) Separate origin reset button on the operation panel

3.4) Roller frequency conversion debugging

4. Thin film system

4.1) The film release mechanism is a free swinging arm with sensitive sensing, and the power pre stretching automatic film supply (stretching ratio of 300%) makes it easy to release the film with just one pull; Save 2/3 of consumables

4.2) The film clamping mechanism on the film frame is safe and fast (the film frame guide roller is made of seamless steel pipe precision machining, wear-resistant and durable; the variable frequency pre tension rubber roller adopts automatic self-aligning bearings, no noise, stable and reliable operation)

4.3) Adopting a dual chain structure, the film frame can be raised and lowered at adjustable speeds, and the film feeding speed can be adjusted

Shandong Shenglong Company: The columns are made of cold-rolled steel plates, with a thickness that fully meets national standards and is sturdy and durable. The guide rails adopt IPEX advanced technology and U-shaped guide rails; It has bidirectional positioning, low noise, and reliable and durable stability in the rise and fall of the film frame, especially for the packaging of ultra-high goods. )